Etfe material

Las siglas ETFE son el acrónimo del Etileno-TetraFluoroEtileno, siendo el material un copolímero de esta molécula. The panels of the Eden Project are also made from ETFE , and the Tropical Islands have a 20m² window made from this translucent material. Another key use of ETFE is for the covering of electrical and fiber-optic wiring used in high -stress, low-fume-toxicity and high-reliability situations. Aircraft and spacecraft wiring are . ETFE constituye una alternativa a los materiales convencionales que permite realizar formas y geometrías imaginativas y singulares para dar forma a edificios más innovadores y espectaculares.

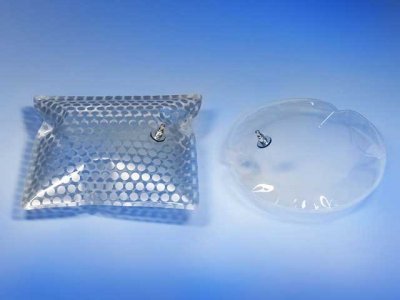

ETFE (Ethylene Tetrafluoroethylene) can be applied in multiple ways such as single, double or triple layered tensile architecture applications.

The material is durable, highly transparent and very lightweight in comparison to glass structures. Originally invented by DuPont as an insulation material for the aeronautics industry, ETFE was not initially considered as a main-stream building material , its principle use being as an upgrade for the polythene sheet commonly used for green house polytunnels. The advantages of its extraordinary tear . Los nombres comerciales más conocidos para el ETFE son Tefzel de Dupont, Fluon de Asahi Glass Company y Neoflon ETFE de Daikin.

DuPont inventó un polímero de fluoro-carbono para ser utilizado como material aislante en la . ETFE is a manmade fluoropolymer which stands for ethylene tetrafluoroethylene, which has attained its position as an efficient architectural material. The appearance of ETFE is like a transparent sheeting material type, which can be employed instead of glass and plastic that are hard in nature. They come in uncountable varieties and each has a specific purpose.

Two of the newest are ETFE and PTFE. These upcoming plastics are increasingly interesting for exterior use. UN MATERIAL PARA LA ENVOLVENTE ARQUITECTÓNICA Desde hace un tiempo, llamativas obras de gran valor arquitectónico han puesto de máxima actualidad un material muy resistente, conocido como ETFE , que se distingue por su poco peso, resistencias mecánicas elevadas y su alta . ETFE is another way of saying Ethylene Tetrafluoroethylene, a translucent polymer sheeting that is used instead of glass and hard plastic in some modern buildings.

One of the most widely-used of these materials is a fluorine-based plastic known as ETFE (Ethylene tetrafluoroethylene). Brought into the public . PTFE is used world wide as the preferred material for large-scale permanent tensile structures. ETFE is not a fabric but a film used as an alternative to structural glass.

Selected references about ETFE properties are. Numerical rating for flame spread is not intended to reflect hazards presented by this or any other material under actual fire conditions. ETFE (ethylene tetrafluoroethylene), is used in applications where impact resistance and good resistance to stress cracking is required. ETFE can be cross- linked by ionizing radiation. NOTE: The information, recommendations and opinions contained herein is only a guide and is intended solely for your consideration, . Besides open structures, material can be used for fully enclosed structures such as atriums and other humidity controlled environments.

It can be applied in a single-layer which is reinforced with small stainless steel cables. Lightweight aluminum extrusions are used at perimeters to stabilize the material and maintain its shape. Its application can also be in double or triple layer cushions which is supported by lightweight aluminum .

The material has many attractive attributes, combining design practicality and structural cost saving . Therefore, the design strategy for cushions for any given size and load combination, is to pattern the cushion to have the least rise for the designated material thickness. Typically, the optimum camber from the neutral axis of the cushion ranges from 6—percent of span. Like most materials , ETFE expands and contracts in .