Sheet metal process

Countless everyday objects are fabricated from sheet metal. En caché Similares Traducir esta página oct. Bending is a metal forming process in which a force is applied to a piece of sheet metal , causing it to bend at an angle and form the desired shape.

LECTURE-14SHEET METAL FORMING PROCESSES Nikhil R. Bending is one very common sheet metal forming operation used not only to form shapes like seams, corrugations, and flanges but also to provide stiffness to the part (by increasing its moment of inertia). As a sheet metal is bent (Fig ), its fibres experience a distortion .

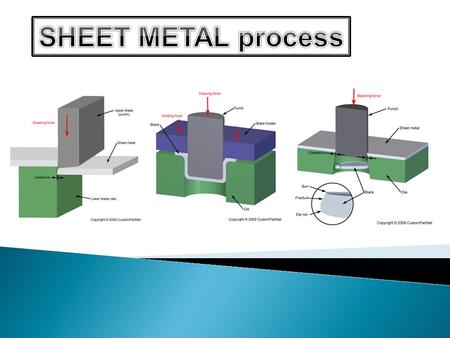

The applied force stresses the metal beyond its yield strength, causing the material to plastically deform, but not to fail. By doing so, the sheet can be bent or stretched into a . The raw material for sheet metal manufacturing processes is the output of the rolling process. Typically, sheets of metal are sold as flat, rectangular sheets of standard size. Schematic illustration of shearing with a punch and die, indicating some of the process variables.

Characteristic features of (b) a punched hole and ( c) the slug. Note that the scales of the two figures are different. A blank is a properly sized piece of sheet metal removed from a much larger sheet or coil by.

In this video we present you the sheet process technology. We can design sheet metal product for you in a. Shearing and Punching Operations. It is performed on power shears, or squaring shears. To reduce the required cutting force upper blade of the power shears is inclined. With the use of the industrial manufacturing process , sheet metal is formed by working metal into flat and thin pieces.

Sheet Metal Forming Basics. Further details about these sheet metal processes are given in the AutoForm glossary. This list compares the good and bad of each process so you can determine the proper one for your own unique requirement. Many translated example sentences containing sheet metal forming process – Spanish-English dictionary and search engine for Spanish translations.

The material that is removed is the new metal workpiece or blank. AMADA provides machines, software, peripheral equipment and consumables necessary for each process in sheet metal processing. Design and draw drawings of sheet metal parts Also calle.

The sheet metal technological process may vary, but not more than the following stated process. The need for sheet metal fabrication arises when an engineering process takes place. In accordance with the engineering requirements, sheet metal is fabricated.